PCB Assembly Equipment in Modern Electronics Manufacturing

Efficient PCB assembly, using advanced machines and tech, optimizes production speed, cost, and quality, crucial for electronics from phones to aerospace.

In the constantly changing panorama of electronic manufacturing, PCBs are an always-present base for almost every electrical device in daily life, from cellphones and laptops to the more advanced systems in aerospace and automotive fields. In these conditions, the efficiency that characterizes the assembly of PCBs will greatly determine the speed, cost, and quality of the final products. In this respect, the equipment for assembling PCBs has grown indispensable in such a significant industry. This article gives in-depth information about types of PCB assembly machines, their characteristics, applications, and a very important role that these machines play in optimizing the manufacturing process at PCBX, which delivers state-of-the-art solutions.

Understanding PCB Assembly

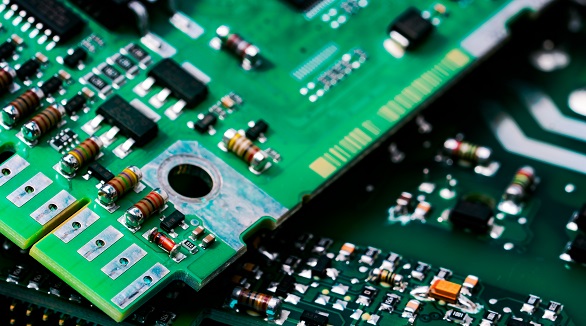

The process of PCB assembly includes attaching electronic components to a bare Printed Circuit Board to turn it into a functional electronic circuit. This process incorporates both surface-mount technology and through-hole technology, each of which has special equipment to automate production and ensure precision.

Types of PCB Assembly Equipment

Soldering Machines

Wave Soldering Machines: These machines are specially designed for THT components. A wave solder machine works by passing the underside of the PCB over a wave of molten solder, creating all the solder connections at one time. The main elements of the equipment include a solder pot, pump, preheating stage, fluxer, and conveyor. Wave soldering is ideal in high-volume production, even though it has limited use in surface mount devices (SMDs).

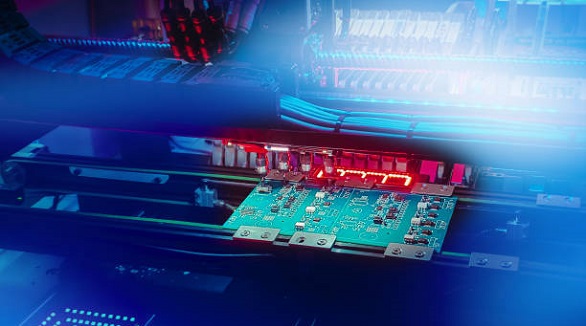

Reflow Soldering Oven: Most suited for SMDs, reflow ovens use a well-controlled heating profile to melt solder paste and secure the components onto the PCB. The preheat, reflow, and cooling stages, all together, give excellent quality to the solder with minimal thermal stress to components. Depending upon the scale of production, infrared or convection heating methodology is used, and with convection heating, a faster heating makes it suitable for mass production.

Selective Soldering Machines: These machines provide the flexibility of soldering selected areas of a PCB using a focused soldering nozzle. The method is essential for mixed-technology boards and comes in very handy in post-reflow applications where only selected heat-sensitive or through-hole components need soldering.

Inspection Machines

Automated Optical Inspection: AOI uses high-resolution cameras to inspect the PCB for defects in solder joints and component placement. AOI systems make quick and accurate defect detection by comparing the assembled board to a known good reference. Sometimes, however, subtle process variations not easily visible to the eye can be overlooked by such systems.

X-Ray Inspection Systems: Capable of capturing detailed internal images of a PCB, these machines are invaluable for inspecting hidden features or multi-layered boards. Although more expensive than AOI, X-ray inspection is required to ensure the integrity of solder joints on complex assemblies.

Flying Probe Testers: Flying probe systems use movable probes to test PCBs for electrical faults such as shorts and opens. This is an agile method, ideal for small batches or prototypes, and offers full electrical testing without requiring dedicated test fixtures.

Material Handling and Cleaning Equipment

Conveyor systems make the transportation of PCBs between different assembly stations smooth, thus minimizing manual handling and thereby reducing the occurrence of human error.

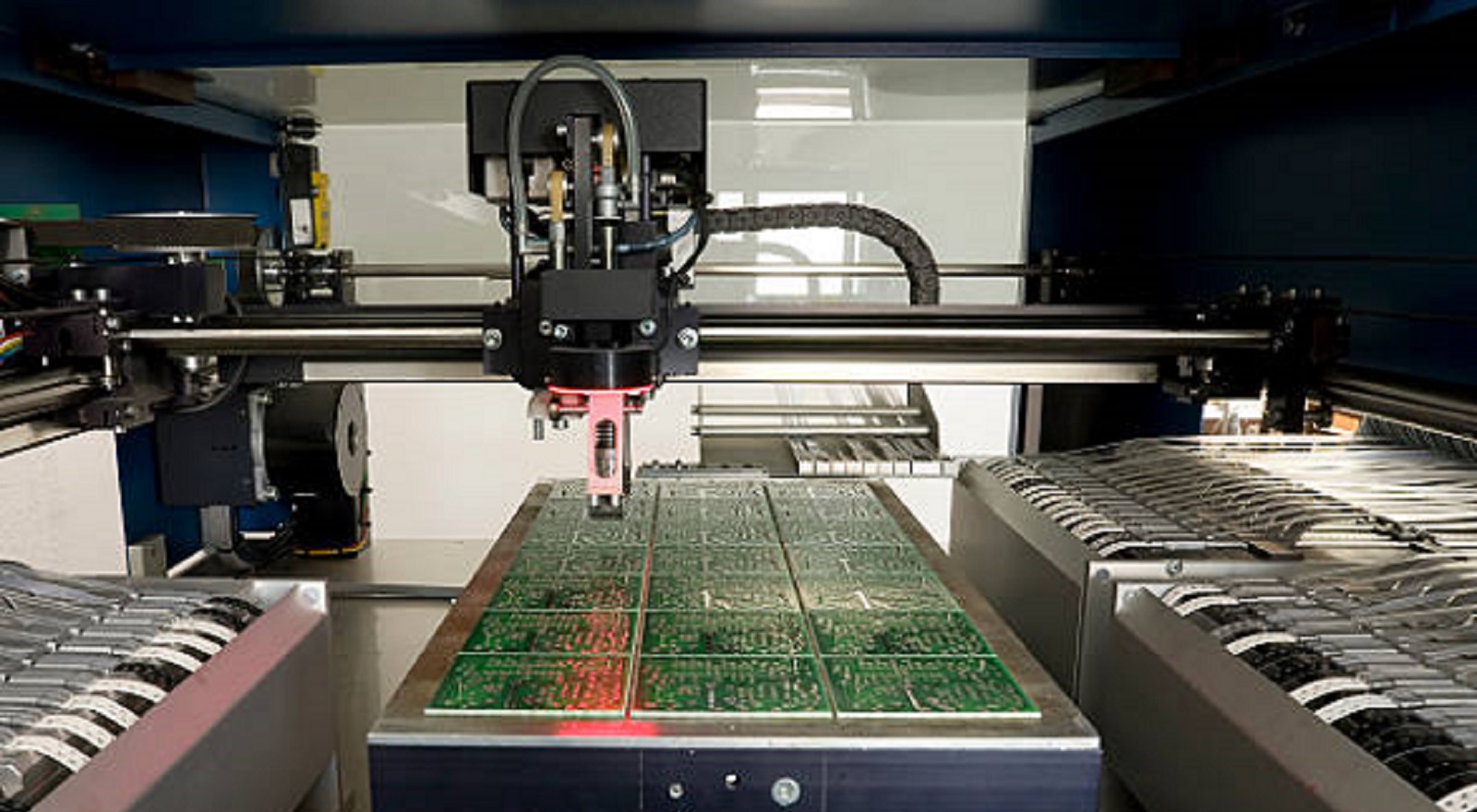

Automatic Solder Paste Printers: These machines apply solder paste to PCBs using stencils. This ensures consistent paste application and minimizes the occurrence of defects due to incorrect paste volumes.

Cleaning Equipment: After soldering, there are often residues of solder flux on the PCB, which should be cleaned off to prevent corrosion and guarantee reliable performance of the board. Several cleaning systems may be used, from washers to special agents.

Rework Equipment

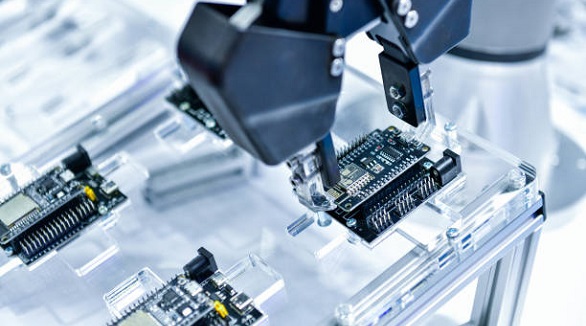

Soldering & Desoldering Stations: These are manual stations that play a crucial role in component replacement or repair of the PCB without affecting other areas of the board. Techniques such as hot air, infrared heating, and vacuum handling improve precision during manual rework.

Fume Extraction Systems: These are used to remove toxic fumes produced during soldering and desoldering operations so that the working area remains in a safe condition for operators.

ESD Control and Auxiliary Equipment

It is important to take precautions against static electricity when working with sensitive electronic components. Special equipment, such as wrist straps, ESD mats, ionizers, and special containers, protects against electrostatic damage.

Selection Considerations for Equipment

Selection of PCB assembly equipment appropriate for the task is critical to obtaining a correct manufacturing result. Factors that have to be considered relate to component type, number of boards produced in any series, precision and accuracy required, budget availability, space in the facility, and operator expertise required. For example, high-volume manufacturing systems may employ wave soldering machines and high-speed component placement machines, while smaller manufacturers may opt for reflow ovens and flexible manual stations.

Suppliers and Industry Trends

The leading suppliers of the PCB assembly equipment include ASM, Juki, Yamaha, and Panasonic, all of them with variable solution offerings. The industry has started to trend toward ever-higher automation, including the implementation of smart manufacturing technologies. These include AI for improved inspection processes and machine learning for predictive maintenance, in a bid to drive up quality and efficiency.

At PCBX, we understand that the right assembly equipment mix is crucial in electronics manufacturing. Having the right combination of equipment will greatly enhance the factors that are driving competitive advantage today: throughput, product quality, and cost minimization. This will become increasingly important as technology continues to evolve; industry trends and innovations in assembly equipment will be key differentiators for companies as this evolution occurs. It is our mission to assist manufacturers in building optimized production lines for their needs, thereby helping foster the next generation of electronic devices that will be dependable and advanced.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Automated PCB manufacturing enhances precision, reduces costs, and accelerates production, enabling efficient, high-quality mass production and customization, vital for industry advancement.

Surface Mount Technology revolutionizes electronics, offering size, cost, and performance benefits, but poses challenges with high setup costs and handling.

Through-Hole Technology (THT) mounts electronic components by inserting their leads through pre-drilled PCB holes and soldering them. While durable and ideal for harsh conditions, THT is less space-efficient than SMT.