What is Metal Core Printed Circuit Board?

Metal core PCBs enhance thermal management in electronics, crucial for LED efficiency and reliability, offering superior heat dissipation and compact design benefits.

In today's rapidly evolving world of electronics, effective thermal management is the order of the day. Among solutions for managing thermal challenges, Metal Core Printed Circuit Boards (MCPCBs) are a tried and trusted one. With LED technology taking center stage, MCPCBs have emerged as a necessity, offering state-of-the-art thermal management and reliability in numerous applications.

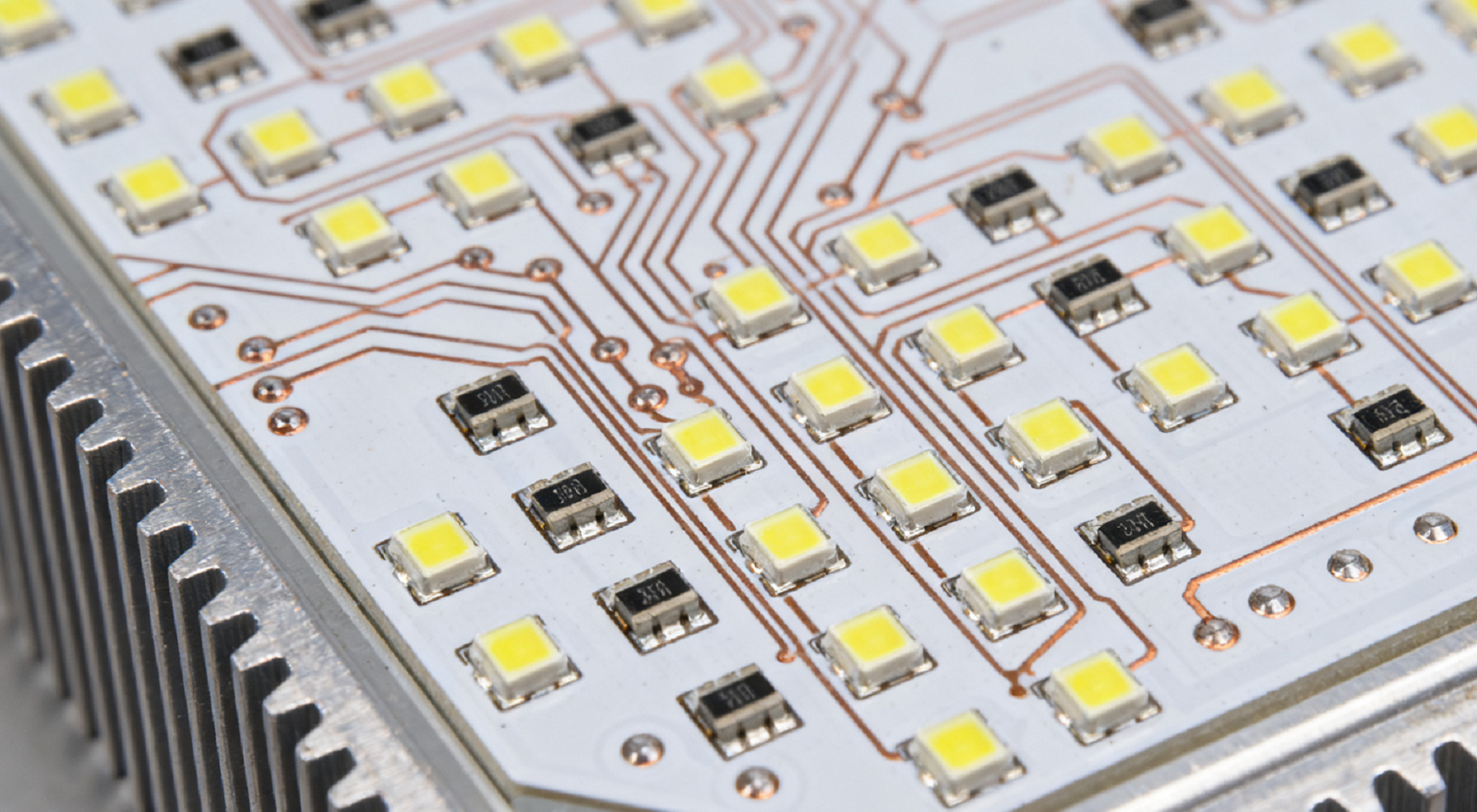

The LED Revolution and the Role of MCPCBs

The unprecedented growth of LED technology has been a driving force behind the expanding supremacy of MCPCBs. LEDs replace traditional lighting options due to their higher energy efficiency and lifespan. LEDs, for instance, can be up to five times lower in cost than incandescent bulbs and offer greater energy efficiencies than compact fluorescents. Moreover, they are so compact that it allows innovative design in a wide variety of applications, ranging from consumer products to industrial light systems.

But LEDs generate enormous amounts of heat that, when not dissipated, impact their performance and longevity. This is where MCPCBs come in. By properly managing heat, they enable maximum performance and extend the longevity of LED systems, which has made them widely utilized not just in lighting but also automotive and consumer electronics use.

What is a Metal Core PCB (MCPCB)?

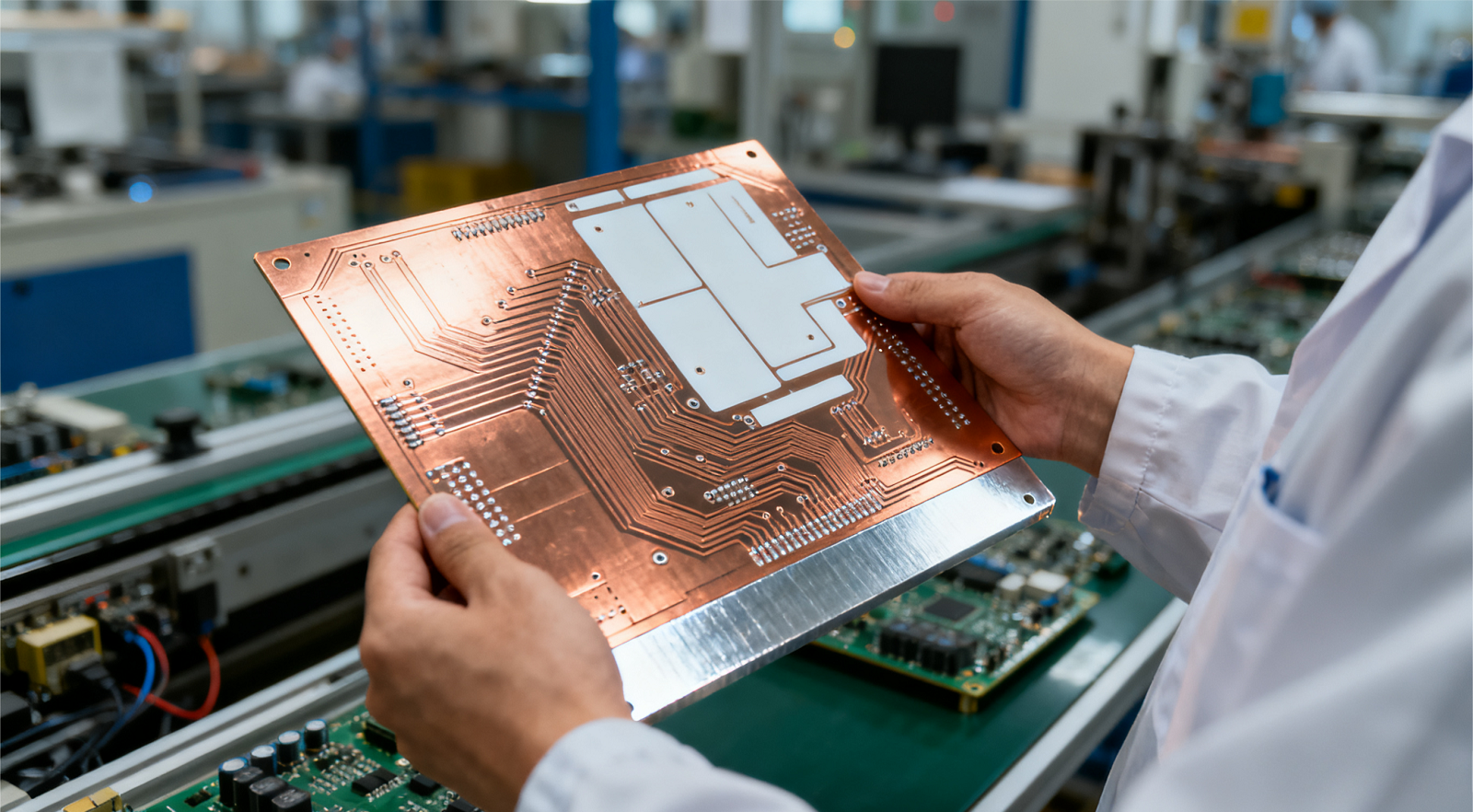

An MCPCB, or metal-backed or thermal PCB, is a specialized type of PCB that utilizes a metal core, typically aluminum or copper, to offer significantly enhanced thermal conductivity. The metal layer acts as a heat spreader, keeping heat away from delicate components to areas where it can be safely dissipated. As compared to conventional PCBs, which typically utilize FR4 or CEM3 materials, the metal core optimally positions itself for enhanced heat dissipation.

Structural Components of MCPCBs

Metal Core Layer: The middle component of the MCPCB is designed to provide mechanical support along with thermal conductivity. The most commonly used material is aluminum due to its excellent cost-to-thermal conductivity. For even better thermal performance in some applications, copper cores are employed, albeit at a premium price.

Dielectric Layer: This is the insulating layer that separates the metal core from the copper circuit layer. It plays a role in facilitating thermal transfer with a restriction on electrical short circuits. The dielectric layer's thermal conductivity determines the performance of the MCPCB as a whole.

Copper Circuit Layer: The top layer, on which the circuitry is etched, can vary in thickness based on the design requirements. This layer is similar to the usual PCBs but benefits from the better thermal management provided by the underlying metal core.

Advantages of Metal Core PCBs

MCPCBs offer numerous advantages that render them extremely well-suited for high-performance electronic applications:

Enhanced Heat Dissipation: With successful dissipation of heat from components, MCPCBs prevent overheating, guaranteeing safe and sustainable performance and long device life.

Mechanical Strength: The metal core adds strength, reducing thermal expansion and mechanical damage due to stress.

Higher Reliability and Lifespan: Electronic components, with enhanced heat management, operate in safe temperature levels, maximizing reliability and lifespan.

Compact Design Options: Thermally efficient design enables more compact formats, which are crucial for today's miniaturized electronics.

Applications of MCPCBs

Applications of MCPCBs are numerous where traditional cooling strategies like fans are inefficient:

LED Technology: MCPCBs are essential in LED lighting applications to provide long-lasting performance in streetlights, automotive equipment, and consumer electronics.

Power Electronics: In power supplies and voltage regulators, MCPCBs contend with the intense heat generated, providing efficient performance.

Automotive and Aerospace: High-reliability applications are able to capitalize on the high-thermal management provided by MCPCBs, critical for systems experiencing thermal and mechanical stress.

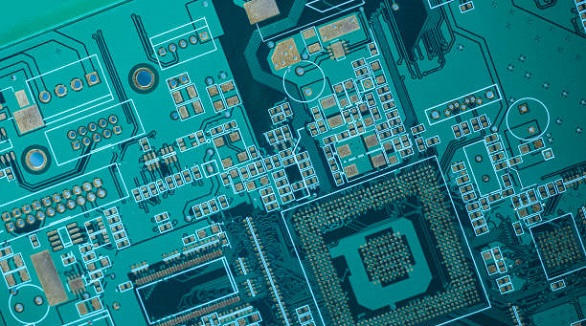

MCPCBs vs. FR4 PCBs

Similar in function but very dissimilar in material and thermal management capability:

Thermal Conductivity: MCPCBs possess much higher thermal conductivity (1.0W to 4.0W) compared to FR4 boards (~0.3W), and thus provide improved heat management.

Structural Variations: FR4 PCBs typically utilize plated-through holes, while MCPCBs prefer surface mount components, which enhance their heat conveyance efficiencies.

Solder Mask and Thickness: MCPCBs possess white solder mask, which is crucial in LED modules for reflective applications compared to dark-colored masks used on FR4 boards, and obey specific thickness constraints regulated by the requirements of thermal management.

Metal Core PCBs are at the forefront of defeating the thermal management issues of modern electronics. Their unique structure and material properties position them at the center of applications requiring heat transfer performance and mechanical reliability. As electronics become smaller and more powerful day by day, MCPCBs' contribution to reliability, performance, and lifespan will only grow.

At PCBX, we are committed to unlocking the full potential of MCPCBs to meet the diverse needs of modern electronic designs. Using our expertise in manufacturing, we offer customized solutions that optimize thermal performance and power efficiency to allow our clients to push electronic innovation to new heights.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Copper balance is key in PCB fabrication, ensuring signal integrity, thermal management, and reliability by managing copper distribution for efficiency.

Choose the right PCB substrate based on application needs, balancing properties like Dk, Df, thermal conductivity, and cost, for optimal performance.

Black FR4 PCBs offer aesthetic and functional benefits, including light blocking, heat dissipation, and enhanced signal performance, suitable for electronics.