What is PCB OSP Surface Finish?

OSP surface finish offers a cost-effective and environmentally friendly solution for protecting copper on PCBs, enhancing solder joint reliability while maintaining performance and enabling reworkability.

In the continuously changing science of electronics production, Printed Circuit Boards (PCBs) are integral components in nearly all technical equipment. The selection of an appropriate surface finish for PCBs is responsible for making them function, be reliable, and endure over a long period. With several options to consider, Organic Solderability Preservatives (OSP) have attracted much attention as they are both economical and environmentally friendly.

The Significance of Surface Finishes

The electrical interconnects on a PCB are ultimately based upon copper's conductivity. But copper is an oxidation-prone chemical metal that forms oxide when exposed to air humidity. This oxidation has critical consequences for high-temperature soldering, reducing the integrity of solder joints and lowering the reliability of finished goods. Therefore, PCB surface finishes play two roles: they keep copper from oxidation and provide a solderable surface for soldering parts.

Introduction to OSP

OSP, Organic Solderability Preservatives, is a type of surface finish that addresses these issues by using an organic coating that maintains copper solderability without interfering with the creation of robust solder joints. The finish involves the deposition of an organic film in the shape of azoles such as benzotriazoles, imidazoles, and benzimidazoles on clean and bare copper surfaces. These chemicals coat copper atoms to form a protective but removable layer upon soldering to prevent oxidation, heat shock, and moisture corrosion and ensure improved solder joint formation.

OSP Manufacturing Process

The OSP process is famous for being easy and efficient and consists of several key steps that ensure the preservation layer quality and efficiency:

Cleaning: This is the initial step that involves the removal of organic contaminants, such as oils, fingerprints, and films of oxidation, to reveal a clean copper surface. Proper cleaning is important in a bid to form an even and stable preservative layer. Concentration levels of the cleaning solutions are closely controlled, and their effectiveness is regularly tested to ensure that the copper surface is of desired quality.

Topography Enhancement: Micro-etching of the copper surface is carried out to eliminate any oxidation and improve the bonding with the OSP solution. There should be stringent control over the etching rate so that there is a constant film thickness. A controlled rate of etching of 1.0 to 1.5μm per minute is required to ensure constant, uniform application of the OSP layer.

OSP Application: Following etching and cleansing, the OSP solution made up of organic compounds is adsorbed on the copper's surface to form a protective coating. Prior to and following application of this, deionized water rinses are employed to prevent contamination and preserve the integrity of the OSP coating.

Benefits of OSP

OSP has been widely adopted within the industry due to a variety of clear benefits:

Cost-Effectiveness: The ease of application and use of inexpensive organic compounds makes OSP a highly cost-effective surface finish, reducing costs of PCB manufacturing overall.

Environmental Friendliness: Chemicals used in OSP, based on water, are free from heavy metals, aligning with initiatives such as RoHS compliance and encouraging eco-friendly manufacturing practices.

Reworkability: OSP coatings can be re-deposited with ease when scratched initially, allowing PCB manufacturers to refresh the finish when needed without significant effort.

Good Wettability: OSP enhances solder wetting, which offers better flux, via, and pad contact, critical in creating good solder joints.

Compatibility with Double-Sided SMT: The application of OSP has been expanded from single-sided to double-sided SMT assembly, making it available for use even in more complex electronic applications.

Less Solder Mask Ink Needed: The characteristic of OSP makes it easier for solder mask designs, which can streamline the PCB production process.

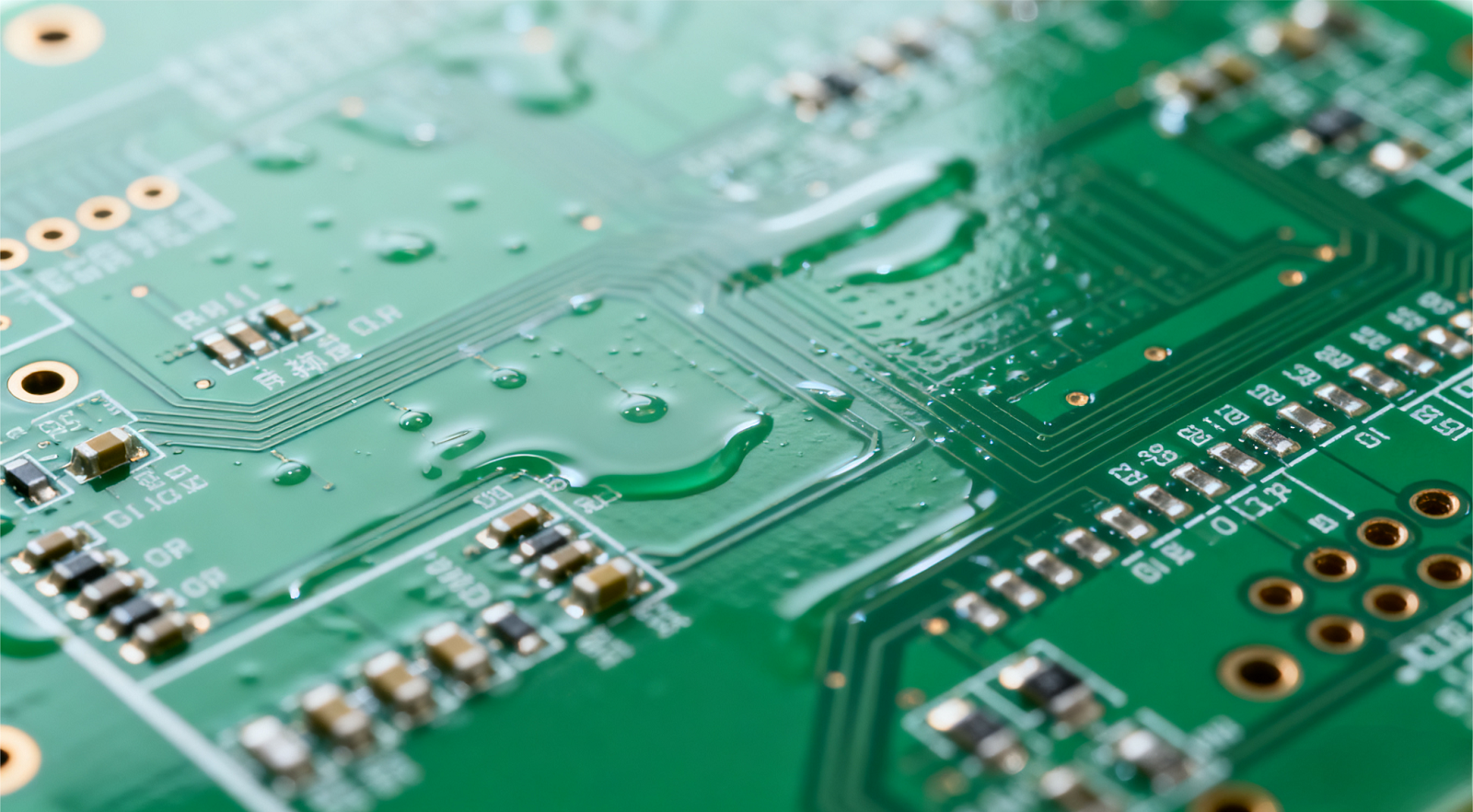

Storage Requirements for OSP-Coated PCBs

Since OSP coating is thin and vulnerable, care has to be taken in storage and handling to prevent oxidation and maintain solderability. Some of the critical storage requirements are:

Vacuum Packing: Vacuum packaging with the use of desiccants and humidity indicators to maintain a stable, low-moisture environment for storage.

Protection from Direct Sunlight: OSP-coated PCBs should be stored away from direct sunlight and exposure to the environment in order to prevent degradation.

Controlled Environment: Storage within a relative humidity of 30-70% RH and temperature range of 15-30°C can extend the OSP coating life for about twelve months.

Post-Soldering Considerations and Challenges

Occasionally OSP boards may display color shifts when soldering and may be a sign of film integrity or contamination issues. These shifts can typically be checked visually and establish whether or not corrective action is required. To optimize soldering performance and appearance, it is important to control OSP thickness, the amount of micro-etching, and removal of contaminants in the PCB manufacturing process.

We at PCBX understand and utilize the full potential of OSP surface finishes to maximize PCB performance and promote sustainable manufacturing. With OSP, businesses are able to successfully counter cost and environmental challenges while sustaining the high reliability and performance of electronic assemblies. Through adherence to rigorous quality control measures in production and storage, OSP can be best utilized to deliver the advantages it has to offer, further establishing its reputation as a broad-spectrum and efficient surface finish solution in modern electronics manufacturing.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Lead-free solder, safer for the environment, requires higher temps and careful handling; lead solder offers ease but poses health and environmental risks.

Gold recovery from circuit boards needs safety gear, precise dismantling, cleaning, etching, and filtering, crucial for safe e-waste recycling.

PCB copper plating is key for creating conductive traces that drive electronic circuits, offering benefits like conductivity, anti-corrosion, and cost-effectiveness. Plating methods include electroless and electrolytic.