PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

PCB edge plating enhances connectivity, mechanical strength, EMC, and thermal management, crucial for diverse sectors, with trends toward higher density and durability.

OSP surface finish offers a cost-effective and environmentally friendly solution for protecting copper on PCBs, enhancing solder joint reliability while maintaining performance and enabling reworkability.

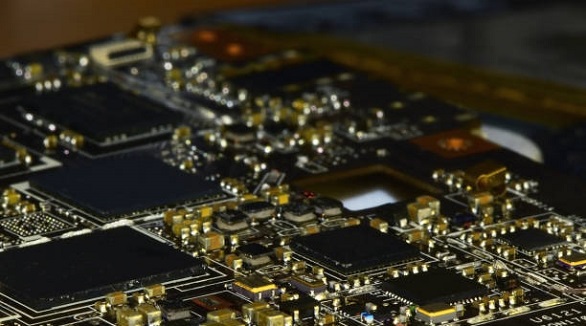

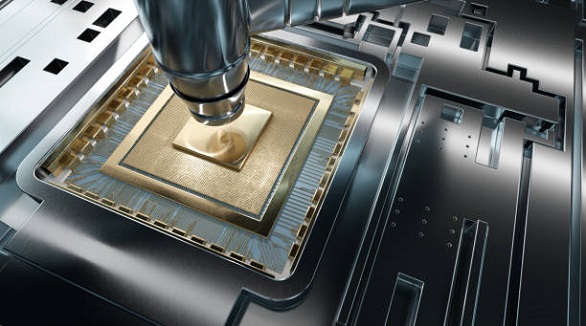

Board and hole plating are essential PCB manufacturing processes, each serving unique roles in ensuring electrical connectivity, mechanical reliability, and overall product quality.

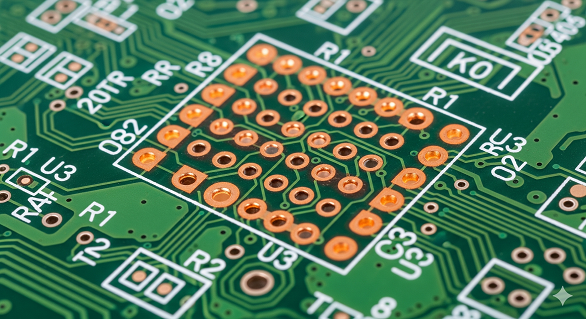

Green PCBs are favored for cost-efficiency, visual clarity, and durable performance, driven by historical and technical factors, with continuous innovations in materials.

White PCBs offer modern aesthetics and enhanced LED efficiency but pose cleaning and inspection challenges, ideal for visually appealing electronics.

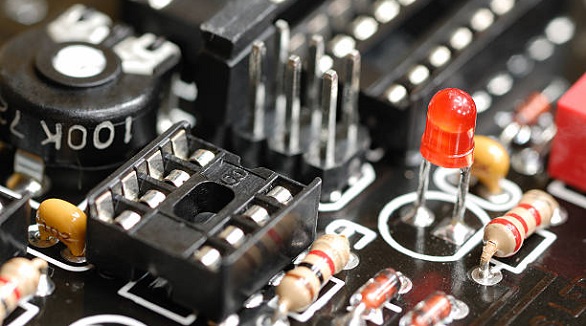

Capacitive circuits store and release energy, stabilize voltage, filter signals, and manage power flow, making them vital for modern electronic systems.

Mini-MELF diode boards offer compact, efficient, and reliable solutions for high-density applications. They excel in electronics, telecom, and evolving tech needs.

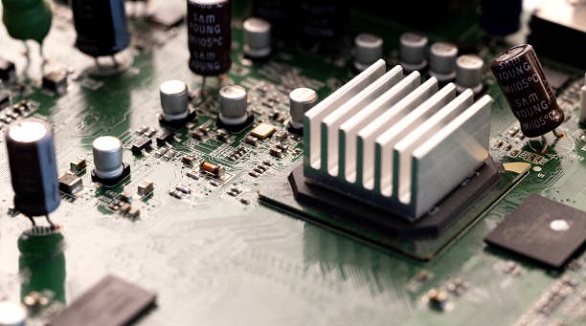

Low thermal conductivity metals, like stainless steel, are ideal for heat retention in PCBs, aiding thermal insulation, efficiency, and stability in electronics.