What is SMT Contract Manufacturing?

SMT contract manufacturing offers cost-efficient, high-quality PCB assembly, allowing businesses to focus on core strengths and adapt to market changes effectively.

In the fast-moving and ever-evolving field of electronics, keeping pace with the market demand and technological advancement is a dilemma that faces every company. Surface Mount Technology (SMT) contract manufacturing is a force to be reckoned with in that context, being a low-cost and high-efficiency solution to provide high-quality electronic products. We at PCBX, understand the inner workings of SMT contract manufacturing and its significance in helping companies manufacture complex electronics without enormous capital expenditures for dedicated equipment and expertise. In this article, we explore SMT contract manufacturing, describing its process, benefits, and strategic relevance in today's tech age.

The Essence of SMT Contract Manufacturing

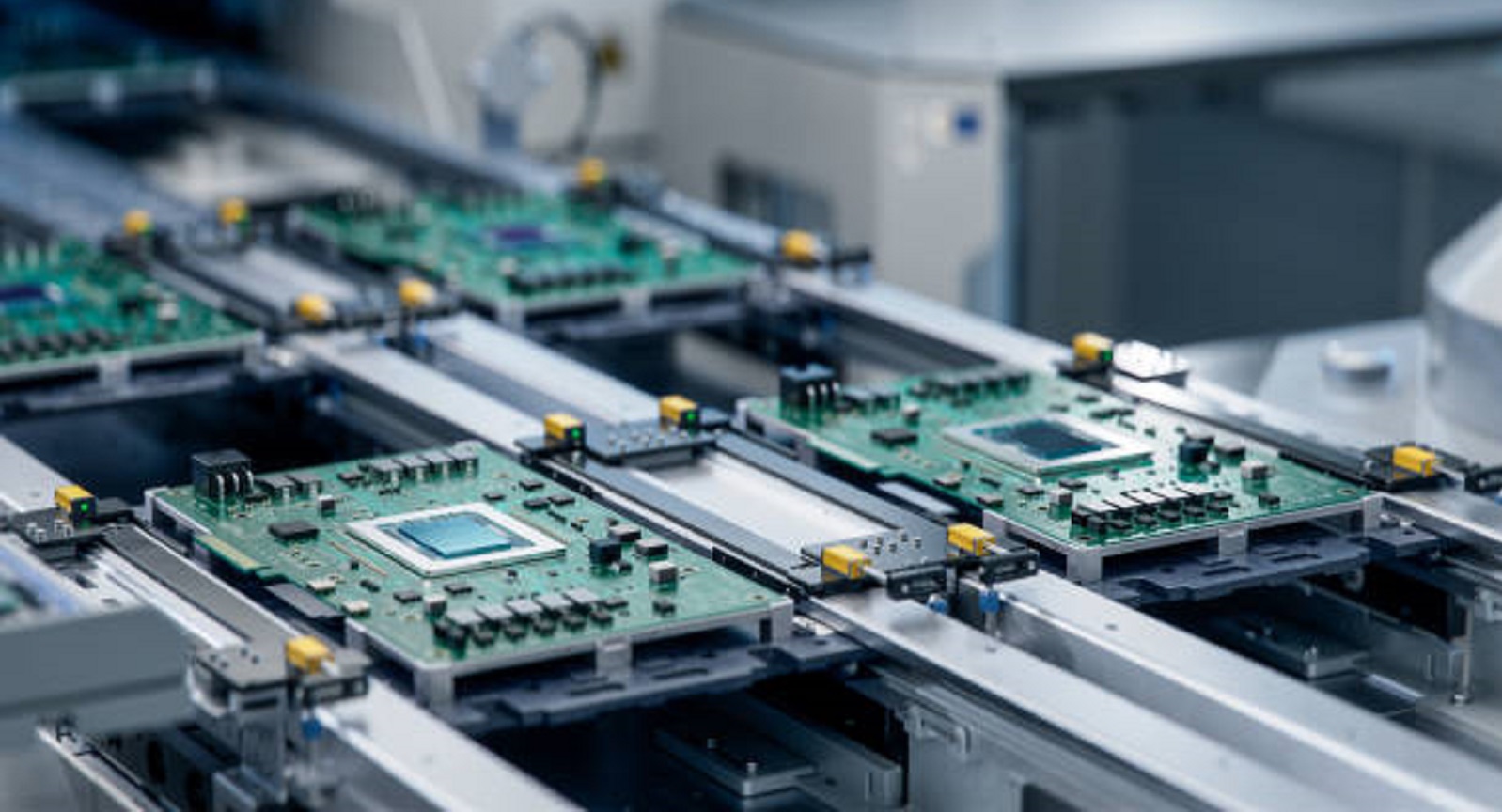

Surface Mount Technology (SMT) is a revolution in electronic circuit assembly whereby components are mounted directly onto the surface of a printed circuit board (PCB). Unlike the traditional through-hole technology that involves inserting the components into holes that are drilled into the board, SMT allows for the components to be mounted on either side of a PCB and hence facilitating miniaturization of smaller, yet efficient and more advanced devices. SMT contract manufacturing offers a turnkey solution by offering specialized services such as design, assembly, testing, and operational logistics, thus making the key technology accessible to various industries like electronics, food processing, and brewing.

Why Choose SMT Contract Manufacturing?

Contract manufacturing of surface mount production is not just an option, out of necessity because of the absence of assets or resources—it is also a strategically sound choice for a number of reasons:

Cost Efficiency: In-house production of SMT is a massive investment in technology, equipment, and skills. With outsourcing, companies can significantly reduce the upfront expenditure, which can be diverted to innovation, research, and market development. Contract manufacturers provide such services at optimal costs, ensuring a return on investment in order to finance long-term business strategies.

Access to Expertise and Quality: Contract manufacturers of SMT are specialists in their domain, constantly learning and evolving their technology to deliver high-quality production outcomes. Their expertise in precise automation and assembly techniques results in products with stringent quality demands, meaning better reliability and performance.

Scalability and Flexibility: Market demands can shift very quickly, and being able to react to these changes is vital to remaining competitive. SMT contract manufacturers provide the flexibility to scale operations effectively, ramping production volumes up or down as required without compromising quality or turnaround times.

Focus on Core Competencies: Allowing the specialists to deal with the intricacies of manufacturing, companies can focus on their core competencies—be it research, product development, marketing, or customer service—while outsourcing the operational execution to contract manufacturers.

The SMT Contract Manufacturing Process

SMT contract manufacturing flow typically follows some critical stages to provide high-quality output:

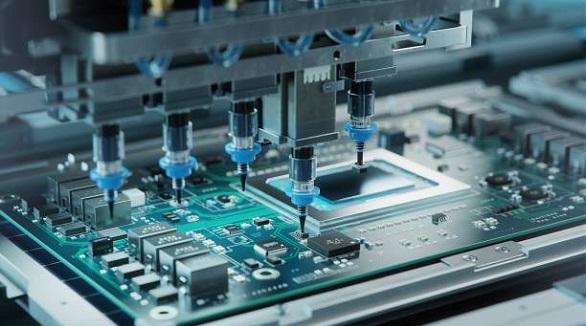

Design and Prototyping: The contract manufacturers typically engage in the design stage to make the products more appropriate for SMT assembly. Prototyping is conducted, allowing trial and testing and maturing of designs to detect and solve potential issues before full-scale production begins, reducing risk and improving the reliability of the final product.

Component Sourcing and Assembly: Founded upon established supplier networks, comprehensive sourcing facilities allow manufacturers to procure quality components at optimum costs. Automated assembly procedures via advanced equipment grant precision placement of components, enhancing structural integrity and function.

Testing and Quality Assurance: SMT production has stringent quality control built in. Advanced inspection techniques guarantee that each product conforms to industry standards of performance, durability, and safety so that only perfect products reach the market.

Logistics and Supply Chain Management: Contract manufacturers typically provide full logistical support, making distribution easy and enabling timely delivery of completed products to customers. This end-to-end set of services reduces the customer's supply chain management overhead and complexity.

Applications and Advantages

Consider an example of a firm facing a sudden demand surge for its products. SMT contract manufacturing is able to absorb this increased demand efficiently, without sacrificing quality and timelines. This allows the firm to focus on strategic business growth without being interrupted by the operations aspect. The following are further benefits:

Professional Fabrication and Component Placement: The manufacturers deliver quality products by performing skilled fabrication, with components placed with utmost precision, which enhances the operational efficiency and life of the product.

Cost Savings: Lower service charges are enjoyed by customers due to the economies of scale in large production possible because of contract manufacturers. End-to-end control over material and processes ensures a cost-focused service model.

Industrial Focus and Assembly Efficiency: With undivided attention to time-critical production, the manufacturers allow customers to remain concerned about bigger business strategies without their attention being diverted by manufacturing issues.

Unmatched Quality Control: Quality is uncompromising at SMT contract manufacturing, with rigorous testing and inspection ensuring that products meet the highest standards, thereby enhancing customer satisfaction and confidence.

Companies outsource to SMT contract manufacturers due to time, resource, or strategic priorities. Outsourcing takes advantage of the manufacturers' expertise to deliver efficient and quality production that leads to market competitiveness. It helps in attaining a smoother cash flow and business scalability that are integral to future growth and success in the competitive environment of today.

In summary, SMT contract manufacturing is a practical, innovative solution for companies to realize today's requirements in electronics manufacturing. By providing strategic advantages in the form of cost-reducing operations, quality enhancement, and responsive scalability, this practice has emerged as a vital part of electronics manufacturing today. At PCBX, we anticipate continued facilitation of enterprises through this challenging yet fundamental process, promoting future advancements in electronic manufacturing.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Ensure SMT quality through detailed design, supplier rigor, and process controls, enhanced by testing and continuous improvement for reliable, defect-free products.

Box build assembly integrates components into complete systems, including PCBs, cables, and enclosures, requiring careful planning and quality testing.

Electronic module assembly is crucial for innovation, driven by demands for high-performance, reliable modules in fields like connectivity and electric transportation.