PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

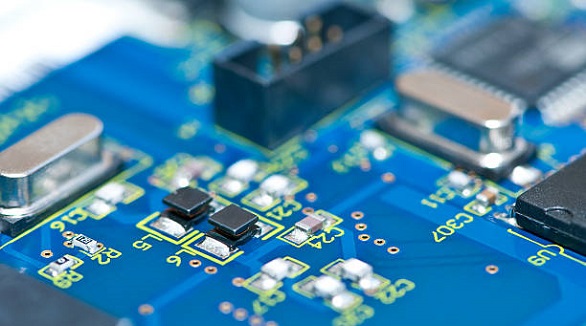

01005 components are key for miniaturization in electronics, requiring precise handling in PCB assembly to overcome challenges in soldering, placement, and inspection.

Choosing between clean and no-clean flux impacts PCB assembly efficiency and reliability. Clean flux suits high-stakes scenarios; no-clean excels in mass production.

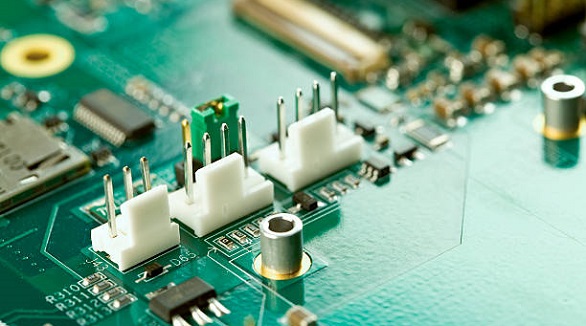

Wave soldering fixtures are crucial for achieving precise through-hole PCB assembly, minimizing defects, and enhancing overall manufacturing efficiency.

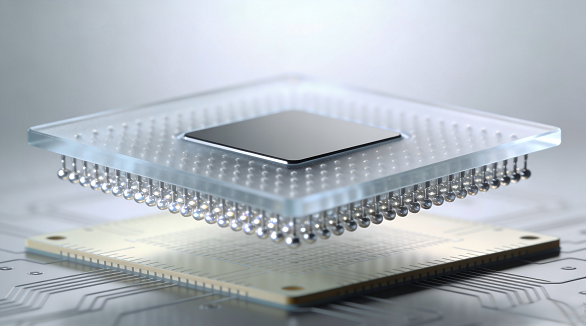

BGAs offer high-density interconnects and compact design, crucial for advanced electronics, but hidden solder joints complicate assembly, requiring precise methodologies.

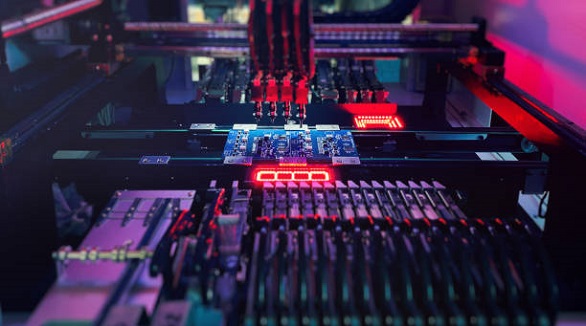

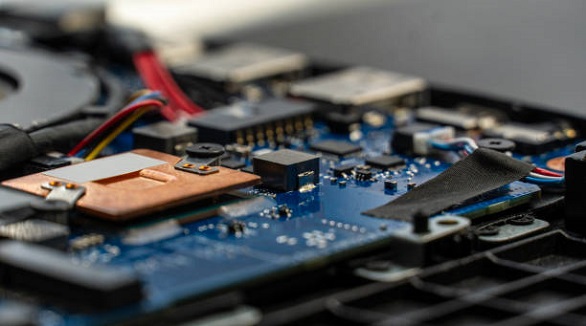

Efficient PCB assembly, using advanced machines and tech, optimizes production speed, cost, and quality, crucial for electronics from phones to aerospace.

EMI protection in PCB manufacturing ensures device reliability and compliance by using shielding, design optimization, and filtering to mitigate electromagnetic interference.

Cable assemblies are essential components that ensure reliable power and data transmission across diverse industries by integrating multiple cables into custom-engineered solutions.

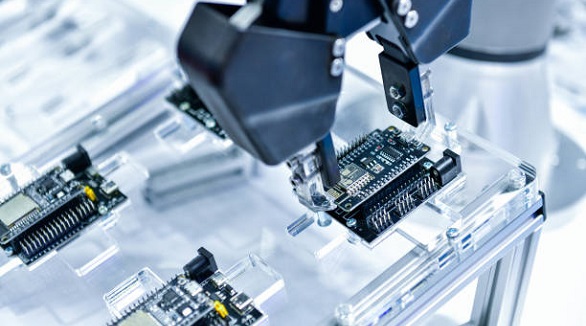

Automated PCB manufacturing enhances precision, reduces costs, and accelerates production, enabling efficient, high-quality mass production and customization, vital for industry advancement.