PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Effective ESD control in SMT assembly is achieved through proper grounding, use of antistatic materials, and routine testing to prevent damage to sensitive electronics.

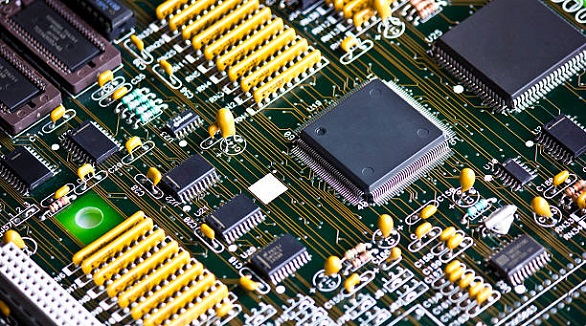

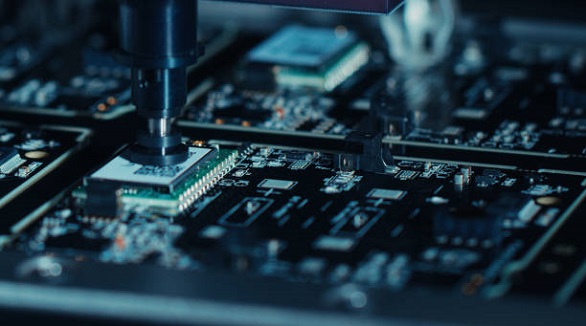

Mixed-technology PCB assembly integrates SMT, THT, and BGA to create compact, efficient electronic devices, meeting the growing demands for high-performance solutions.

SMT contract manufacturing boosts efficiency and lowers costs for electronics businesses, offering advanced technology access and allowing them to focus on essential operations.

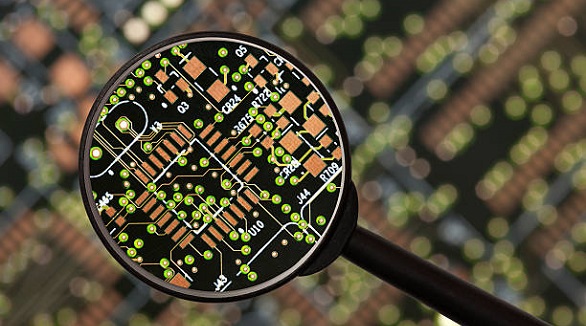

SMT footprints are critical PCB designs for mounting components directly, ensuring electrical connections and standardization, aiding efficient manufacturing.

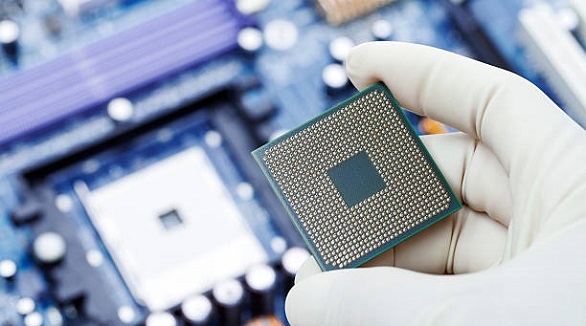

BGA chips offer compact, high-performance mounting for PCBs, essential in modern electronics, but require precise handling and advanced inspection methods.

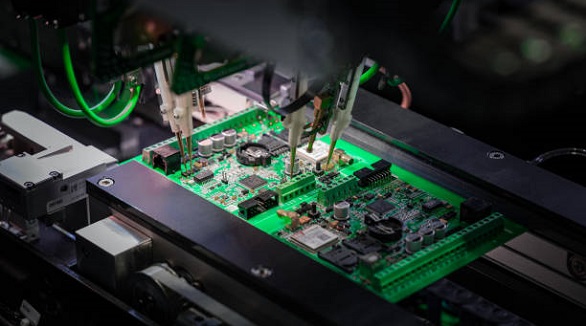

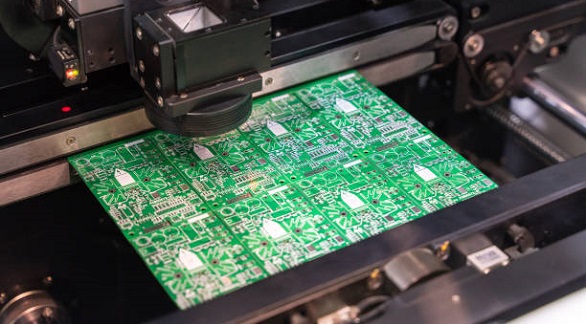

SMT ensures compact, reliable electronics production but requires precise quality control, advanced tech, and skilled workforce to maintain high standards efficiently.

SMT red glue stabilizes components on PCBs, crucial for heavy or dual-sided boards, enhancing assembly reliability and optimizing production costs.

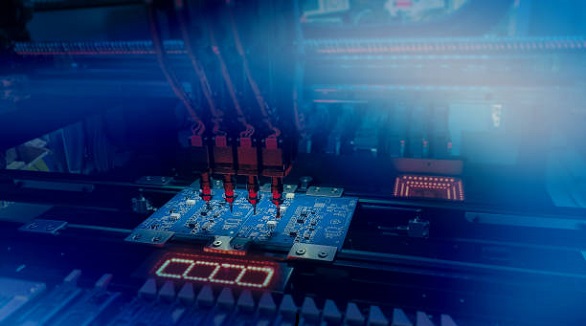

FAI in SMT ensures product quality by detecting defects early, using methods like AOI and X-ray, ultimately enhancing efficiency and customer trust.