PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Choosing between clean and no-clean flux impacts PCB assembly efficiency and reliability. Clean flux suits high-stakes scenarios; no-clean excels in mass production.

Wave soldering fixtures are crucial for achieving precise through-hole PCB assembly, minimizing defects, and enhancing overall manufacturing efficiency.

BGAs offer high-density interconnects and compact design, crucial for advanced electronics, but hidden solder joints complicate assembly, requiring precise methodologies.

EMI protection in PCB manufacturing ensures device reliability and compliance by using shielding, design optimization, and filtering to mitigate electromagnetic interference.

Cable assemblies are essential components that ensure reliable power and data transmission across diverse industries by integrating multiple cables into custom-engineered solutions.

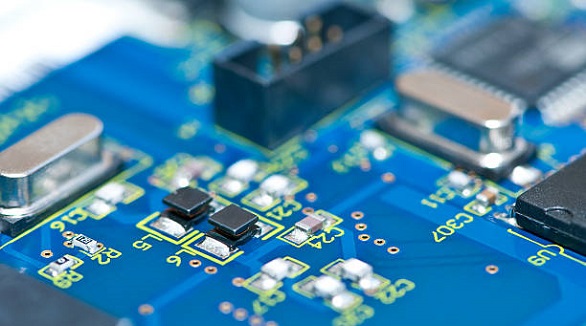

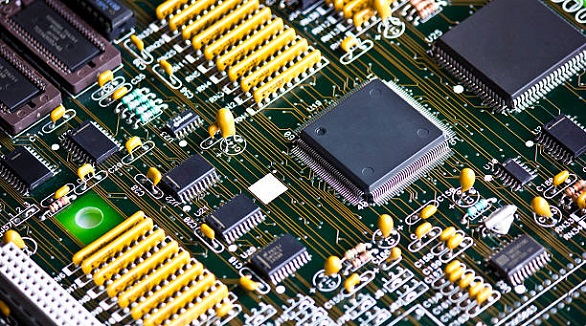

Mixed-technology PCB assembly integrates SMT, THT, and BGA to create compact, efficient electronic devices, meeting the growing demands for high-performance solutions.

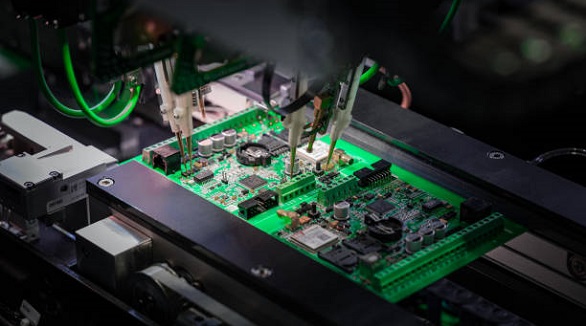

SMT contract manufacturing boosts efficiency and lowers costs for electronics businesses, offering advanced technology access and allowing them to focus on essential operations.

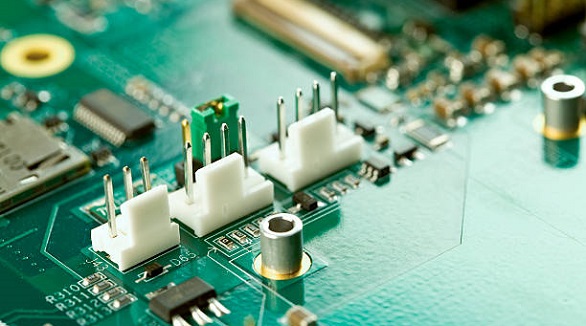

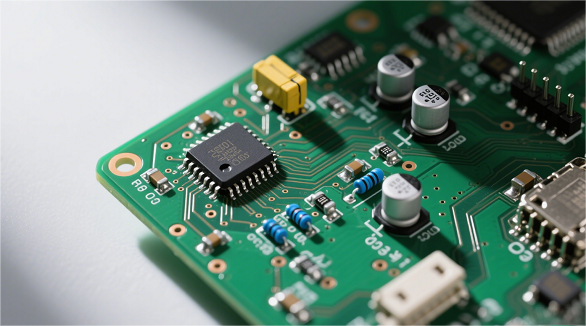

Electromechanical parts assembly integrates mechanical and electronic components for optimal device function, vital in modern PCBs and tech innovation.