PCB Hot Plates in Modern Electronics Manufacturing

PCB hot plates ensure precision in soldering for reliable electronic components, crucial for modern devices, enhancing efficiency through controlled heating.

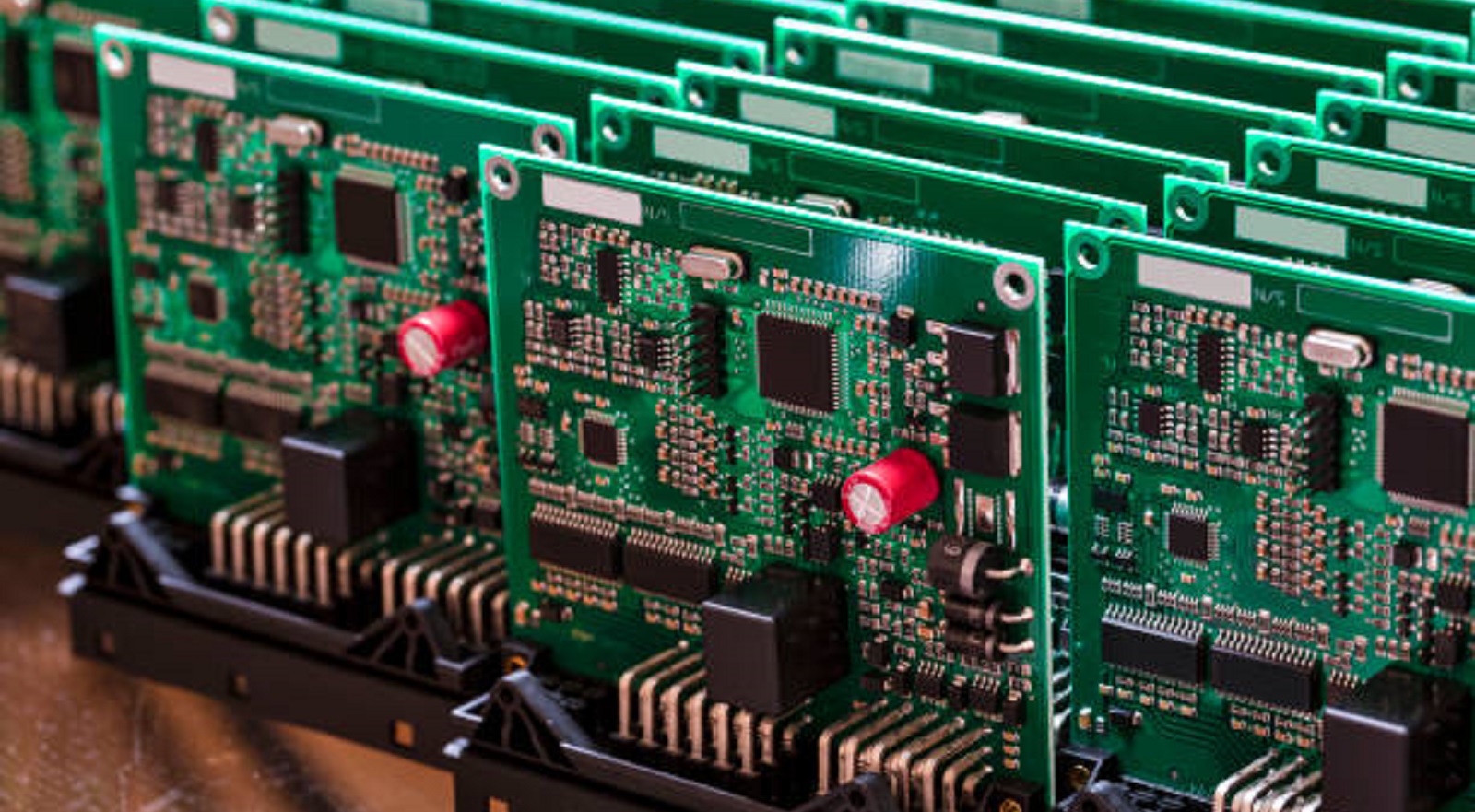

Precision, efficiency, and reliability are non-negotiable in electronic manufacturing. From smartphones to complex industrial systems, virtually all of the devices we use today depend on printed circuit boards. At the core of the manufacturing process of such printed circuit boards is a crucial process that involves the use of PCB hot plates. The hot plate has surely proven to be a vital precision tool through which manufacturers are able to provide quality, reliable products by carefully managing the soldering process. Herein, we review some innovations and methodologies that are involved in the field of PCB hot plates, with an emphasis on their vital contribution toward modern electronics manufacturing.

Understanding PCB Hot Plates and Functionality

The electronically heated PCB hot plates are for precision temperature control applications to maximum temperatures of 300°C. This controlled heating is essential during the baking, reflow, and preheating of rework stations in SMD soldering. Hot plates help the curing of solder paste prior to placing surface mount components and enable the reflow of lead-free solder after assembling for durable and reliable electronic equipment with performance under harsh conditions.

The Working Principle of the PCB Hot Plates

A standard PCB hot plate will contain a number of key elements:

Ceramic Heating Platform: Provides a flat thermally conductive surface for PCB support.

Temperature Controller: Utilizes a closed-loop precision system to energize heating elements for accurate temperature maintenance.

Insulated Housing: Reduces heat loss from the system, thereby increasing its efficiency.

The heating element can be precisely controlled with a feedback loop from embedded sensors, which can provide temperature uniformity and stability within a narrow tolerance of +/- 2°C. Some higher-end models may include vacuum holders that secure boards during reflow or rework, preventing them from moving around and causing soldering defects.

Key Hot Plate Specifications

When choosing a hot plate for PCBs, it's important to know about its specifications:

Temperature Range: Shall extend to at least 150°C, accommodating most soldering applications.

Plate Size: Should be large enough to fit the largest PCB intende d for heating, with even coverage.

Control Stability: Consistency within ±2°C ensures repeatable precision in heating.

Heating Rate: Up to 10°C/sec to support rapid reflow.

Vacuum Strength and Programmability: Prevents warping and allows for customized thermal profiles for different soldering applications.

Improved Solder Joint Integrity

The temperature across the PCBs should be uniform during soldering, and hot plates are important for such purposes. Traditional means usually involve uneven thermal gradients that will most likely make the boards warp and reduce joint integrity. The bottom-side heating provided by the PCB hot plates ensures even solder reflow and reduces issues related to thermal expansion.

Methodologies of Using PCB Hot Plate Optimally

High-quality soldering results depend on careful preparation and execution of the operation, based on comprehensive knowledge of components, solder paste, and the soldering process itself.

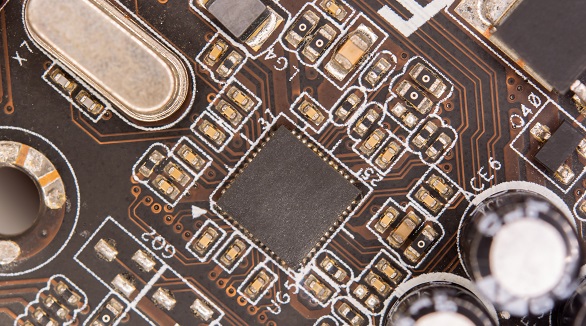

Component Sizing Considerations on PCBs

Sizing and placing components selectively is equally important:

Avoid Large Metal-Cased Parts: Since they have a great deal of thermal mass, they demand more heat and tend to slow the process.

Use Small Surface-Mount Packages: Like 0402/0603 passives that reduce the reflow time.

Centralize DevicePlacement: This ensures positioning within the heated area and avoids any edge-related issues.

Strategically grouping similarly sized SMD parts can assist in batch soldering, but for complex boards, these layout considerations must be weighed against electrical performance needs and routing congestion.

Solder Paste Selection

Key factors in the selection of solder paste include:

Smaller Pitch Devices: Type 3 powder is used to limit solder balling.

Thermal Conductance: High-conductance paste promotes heat transfer, which is essential for effective reflow.

Flux and Alloy Compatibility: Ensures efficient solder joint formation with minimal cure time.

An understanding of the properties of solder materials and interfacial combinations is crucial when evaluating paste options to optimize both process and result.

Usage Protocol of PCB Hot Plate

A well-defined protocol secures the best results in soldering.

Temperature Profiling: Establish the optimal settings through thermocouple monitoring, gradually ramping temperatures to identify the ideal thermal response with each board.

Flux Application: Apply minimal rosin flux to improve the wetting characteristics of the solder without leaving residues.

Solder Paste Dispensing: Use stencils for accurate deposition, making sure of full pad coverage and correct placement.

Component Placement: Properly align the components with either manual precision or automated systems that avoid problems like tombstoning.

Profiling Reflow: The heating cycle shall be controlled such that solder flow and joint formation are consistent. Set temperatures 30-70°C above liquidus point of the paste.

Residual Flux Cleaning: Electronic cleaners of appropriate grade remove residues to preserve electrical integrity and prevent leakage.

Inspection: Confirm solder quality, fill, and alignment are within specification to ensure joint reliability, with no extraneous solder spikes or alignment discrepancies.

Advanced Techniques and Maintenance

Advanced techniques, like vapor phase or photonic reflow, will further optimize solder quality. Besides that, good maintenance of the hot plate itself includes sensor recalibration, controller firmware updates, and cleaning the heating surfaces.

Safety Precautions

Exercise caution with hot plates to avoid hazards:

Use Protective Gear: Hand gloves to avoid skin exposure to high temperatures.

Monitor Environment: Follow maximum temperature ratings so that flammable materials do not ignite.

Stability: Make sure the boards are fully supported on the heated platform to avoid shifting of components.

Allow Cooldown: Let the unit adequately cool down between consecutive uses to prevent damage due to excess heat.

Modern electronics manufacturing relies on the accuracy, flexibility, and speed of PCB hot plates. These devices are crucial in ensuring consistent heating for the realization of reliable solder joints, which define the quality of an electronic component. With ongoing developments in PCBs, lateral heat sources that can be integrated into the manufacturing process will further boost processes and address the pressures on efficiency due to the rise of miniaturization and further complication of electronic devices. The optimization of PCB hot plates will thus not only be desirable but also compulsory for manufacturers intent on quality improvement of their products.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Board and hole plating are essential PCB manufacturing processes, each serving unique roles in ensuring electrical connectivity, mechanical reliability, and overall product quality.

PCB plates provide vital support and customization in keyboards, impacting stability, sound, and performance, underpinning electronic design and evolution.

PCB copper plating is key for creating conductive traces that drive electronic circuits, offering benefits like conductivity, anti-corrosion, and cost-effectiveness. Plating methods include electroless and electrolytic.