Resistor Power Rating in PCB Design

Understanding resistor power ratings in PCB design is crucial for ensuring circuit reliability, thermal efficiency, and preventing overheating through strategic layout and derating.

In the domain of electronic engineering, it can be stated that the use of resistors is one of the most crucial elements required for the proper control of the current as well as for maintaining circuit integrity. In addition to identifying the right resistance value for the circuit, it is essential to evaluate one of the most critical aspects of designing electronic circuits and Printed Circuit Boards (PCBs), namely, the power rating of the resistor.

Understanding Resistor Power Rating

Power rating for resistors refers to the highest amount of power the resistor is able to handle without destroying it. The amount usually comes in watts and expresses that such amount can bear the thermal energy produced during operation. When a resistor is subjected to exceeding its rated power, it might overheat and drift its resistance value or fail catastrophically, hence terminating circuit functionality.

Power Dissipation Calculation

Power dissipation To safely operate your resistor, you will have to calculate its power dissipation accurately. You will use the following formula:

P = V × I

Where you know the resistance, R, and current, I or voltage, V alternative formulae are given by:

P = I2 × R

P = V2 / R

These calculations give the amount of heat generated within the resistor. Choosing resistors with a power rating higher than the maximum that has been calculated provides a safety margin, safeguarding your circuit against thermal stress.

Key Factors Influencing Resistor Power Rating

There are several critical factors that affect the power rating of a resistor that need to be considered very carefully during the design:

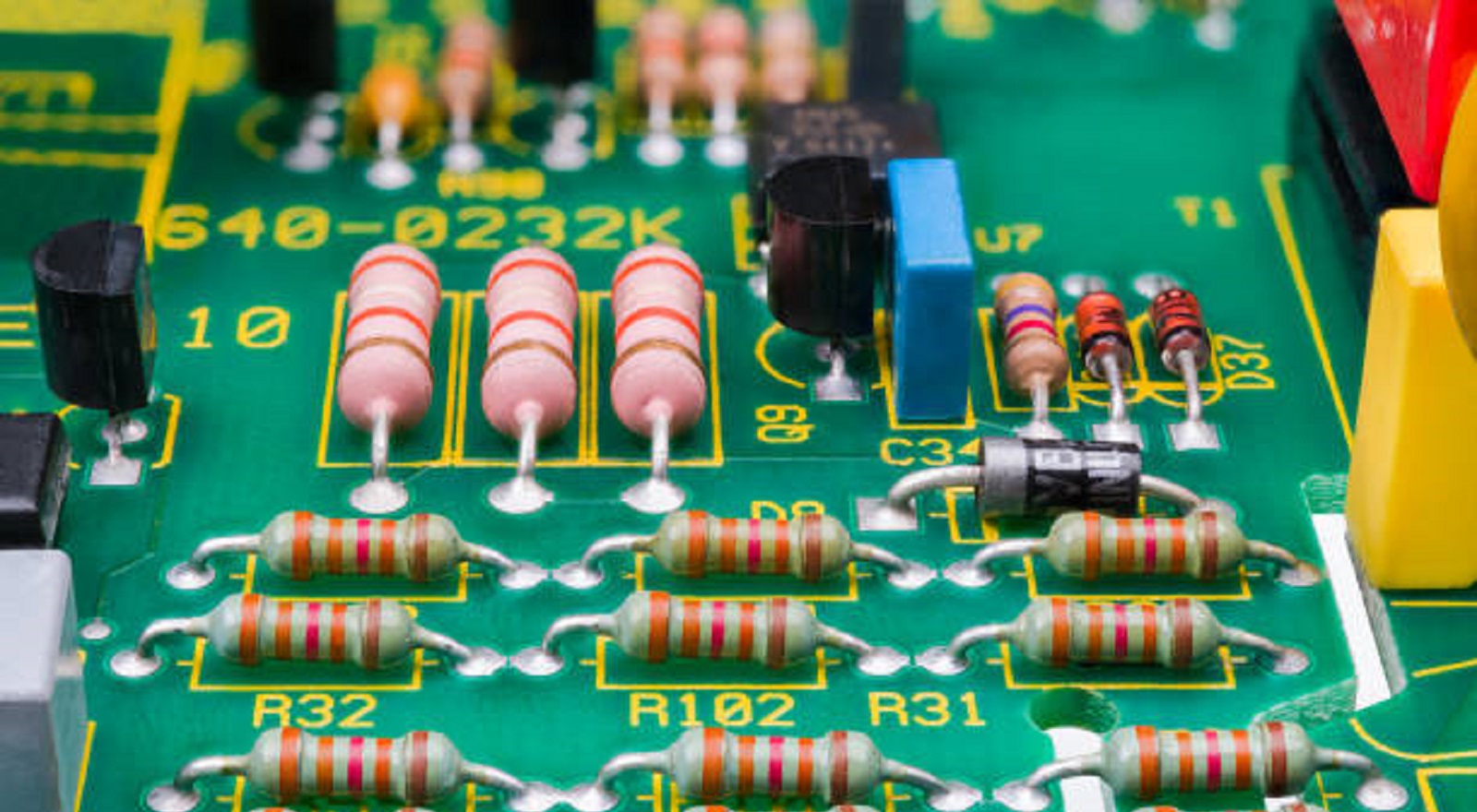

Physical Dimensions and Materials:

Most importantly, power rating is greatly dependent on physical resistor size and choice of resistance material. Larger resistors, usually using wire-wound or thick-film materials, can handle higher power ratings since they tend to dissipate heat more effectively than smaller resistors.

Ambient Temperature:

The resistor performance is influenced heavily by the surrounding environment. In fact, with an increase in the ambient temperature, the ability of a resistor to dissipate heat goes down, thus requiring something called derating. This, in turn, is a practice of operating the resistor below the maximum rated power to improve its reliability under different temperature changes.

Mounting Techniques and Thermal Considerations:

The technique applied for the mounting of the resistor on the PCB contributes greatly to its heat dissipation performance. The processes of heat management specific to this project and the placement of components for optimal air circulation can help reduce heating.

Resistor Power Rating Considerations in PCB Design

Successful implementation of resistor power ratings within PCB design requires a holistic approach where the priority is on thermal efficiency and reliability:

Improving Thermal Removal

The power rating is a key part of your overall thermal design plan. The power rating is how much heat your resistor will handle. In the design of PCB, it is important that you:

Execute Strategic Layouts

The PCB can be designed in such a way as to include the necessary spacing as well as thermal reliefs to allow for the dissipation of heat.

Use Heat Sinks and Ventilation

In high-power use cases, it may be a good idea to add other cooling options like heat sinks or board ventilation.

Managing Risks via Derating

Derating is selecting a resistor that is operated in a reduced capacity compared to its highest possible rating, in consideration of practical application requirements. In most cases, engineers usually apply a factor of 1.5 to 2 times when calculating power dissipation.

Layout Considerations

The actual location of components on the PCB has an effect on thermal issues. Resistors must be located such that:

Heat Distribution is Even: Resistors that are aptly positioned ensure minimal accumulation of heat near those positions.

Minimize Thermal Coupling: High power components must be isolated away from heat-sensitive components.

Practical Steps to Effective Power Management

The following steps can be taken to ensure resistor reliability and effectiveness in the circuit:

Precise Power Requirement Prediction:

The starting point for getting accurate estimates of expected power dissipation has to be circuit specification.

Assess Environmental Realities:

Consider the operational environment, gauging temperature variability and spatial constraints, among other factors to inform the choice of appropriately rated resistors.

Optimize Component Placement:

Effective positioning of the board enables heat dissipation and prevents thermal concentration.

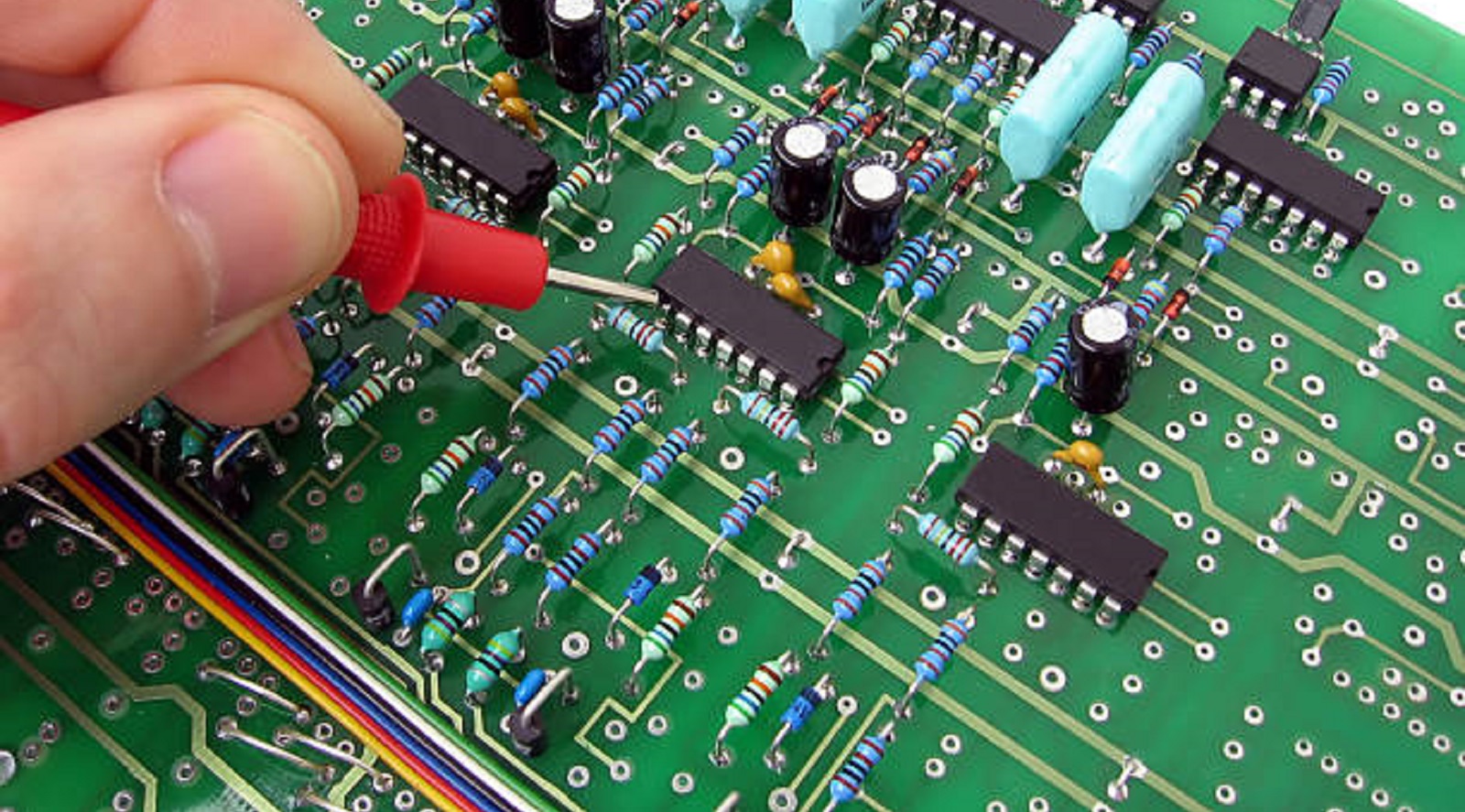

Ongoing Monitoring and Testing:

Make use of thermal imaging or sensors to detect potential hot spots and thereby avoid any failure of a component.

Common Mistakes to Avoid

While carrying out these methods, avoid some of the common mistakes that can lead to circuits underperforming:

Neglect of Guidelines for Derating: Operating a resistor at its nominal limit, without derating, can result in early failure due to extreme thermal conditions.

Incorrect Calculation of Power: All the voltage and current measurements must be actual operating conditions to avoid underestimation.

Poor Heat Management Practices: This would also include allowing space between resistors to avoid overheating in confined spaces, which could lead to damage.

Resistor power ratings and their applications in the design of a printed circuit board are concepts that should be well understood if one has to design a safe and functional circuit. With this knowledge incorporated into your designs, you are guaranteed a more durable circuit. Knowledge on the use of resistor power ratings in the design of a printed circuit board is vital for designing effective electronics.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCB failures due to minor orientation and polarity errors can impact reliability, but proper design practices and checks ensure manufacturability and performance.

Capacitors are crucial in PCB design for filtering and timing. Correct polarity in electrolytic and tantalum types prevents malfunctions and ensures reliability.

PCB design trends include miniaturization, advanced materials, sustainability, automation, and security, aligning with technological advances and diverse industry demands.