PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

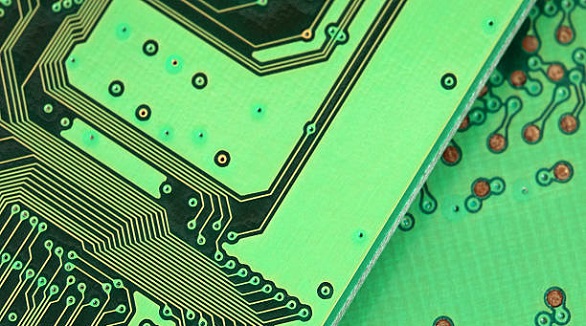

Proper trace-to-pad clearance in PCB design ensures safety, signal integrity, manufacturability, and longevity, following standards like IPC 2221 for optimal performance.

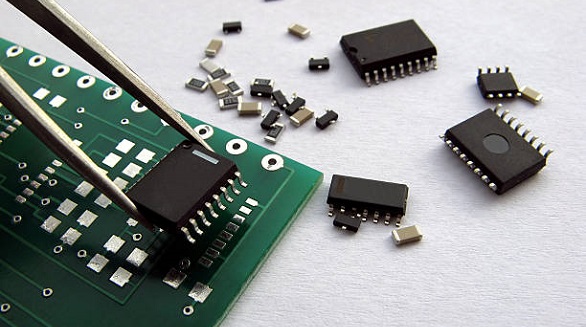

SMT footprints are critical PCB designs for mounting components directly, ensuring electrical connections and standardization, aiding efficient manufacturing.

Lifted pads disrupt PCB performance due to thermal and mechanical stress. Solutions involve better design, materials, and handling to ensure reliability.

Castellated pads in PCB design facilitate easy board-to-board connections, enhancing miniaturization, assembly, solder quality, and flexibility for compact modules.

The 3.3K resistor is vital in electronics for current regulation, is widely available, and ideal in precision circuits, ensuring stability and cost-effectiveness.

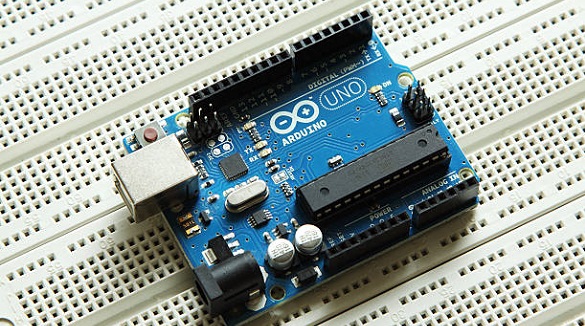

FPGAs with Arduino, like MKR Vidor 4000, enhance electronics prototyping with high flexibility, real-time processing, and customization for diverse applications.

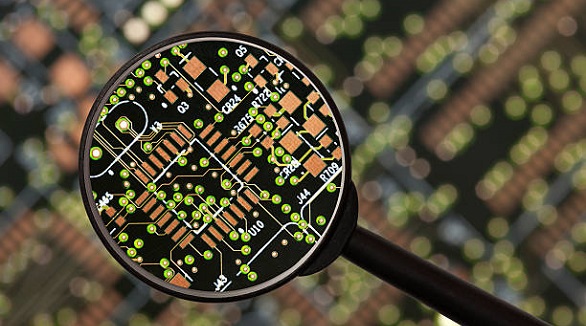

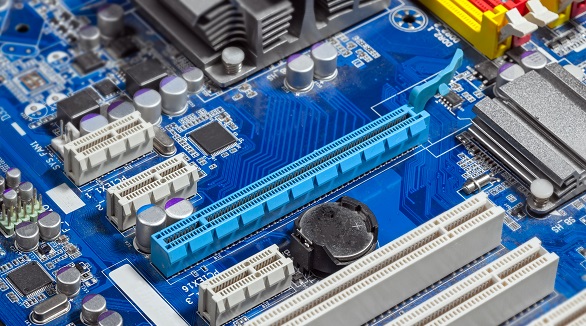

Visual components streamline design and simulation in manufacturing, improving communication, user experience, and efficiency, especially for PCB production.

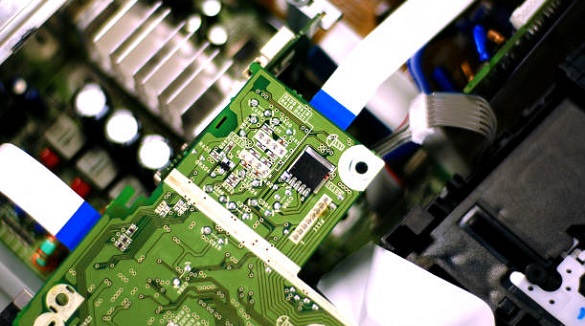

PCB standoffs secure PCBs by spacing them, aiding in thermal management and vibration absorption. They're key for durability and adaptability in electronics.