PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

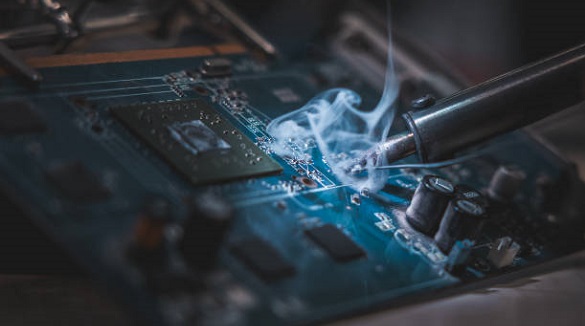

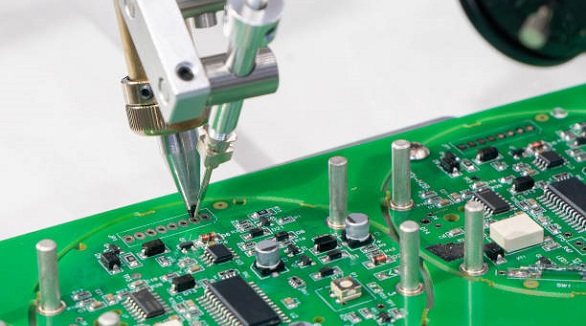

Wave soldering, crucial for assembling PCBs with through-hole components, remains vital for producing strong joints efficiently, despite SMT advances, by optimizing key parameters.

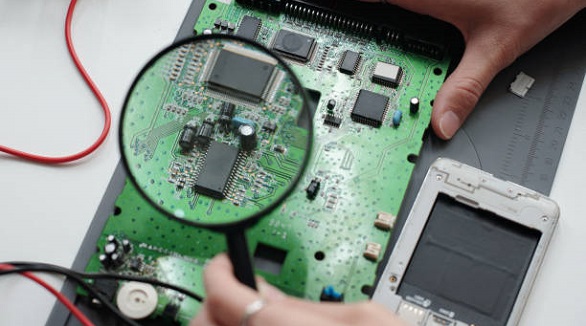

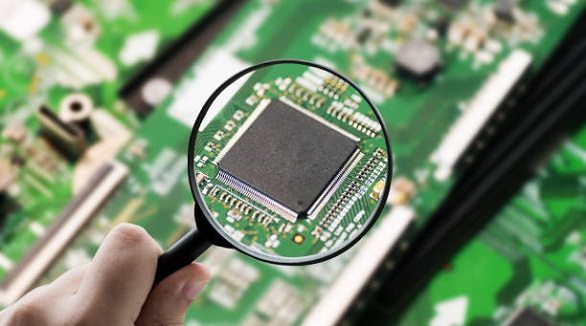

Circuit boards are essential for electronics but susceptible to failures; this guide details efficient diagnosis and repair techniques to ensure device reliability and safety.

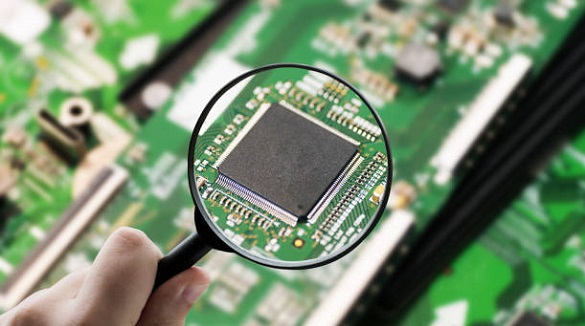

AOI enhances PCB production by providing precise, automated inspections that improve quality and reliability while reducing costs and errors.

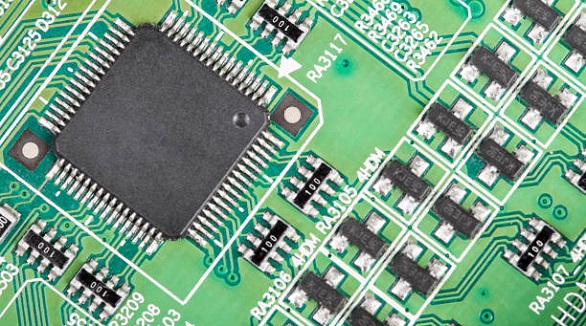

PCB failure analysis ensures reliable electronic devices by diagnosing defects, addressing manufacturing challenges, and optimizing design for improved performance.

Testing diodes with a multimeter is crucial for ensuring reliable performance and preventing failures in electronic appliances by directing current flow effectively.

IPC Standards ensure quality, consistency, and global compatibility in PCB assembly, essential for innovation and reliability in electronics manufacturing.

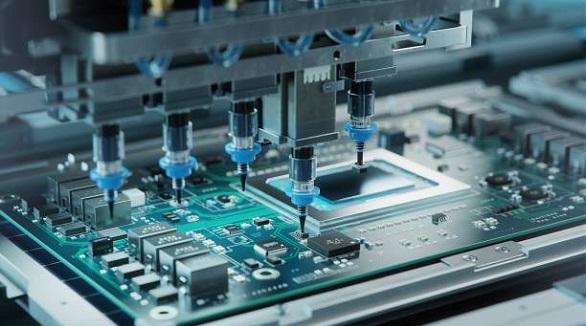

Rigorous PCB inspections using AI, AOI, and X-ray technology ensure high quality, reduce costs, and enhance efficiency in electronics manufacturing.

PCB test fixtures provide essential connections for precise testing, ensuring PCBs meet design specs and allowing seamless production and quality control.