PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Copper wrap plating enhances PCB reliability and performance by strengthening connections, reducing thermal stress, and meeting industry standards like IPC 6012E.

OSP surface finish offers a cost-effective and environmentally friendly solution for protecting copper on PCBs, enhancing solder joint reliability while maintaining performance and enabling reworkability.

Metal core PCBs enhance thermal management in electronics, crucial for LED efficiency and reliability, offering superior heat dissipation and compact design benefits.

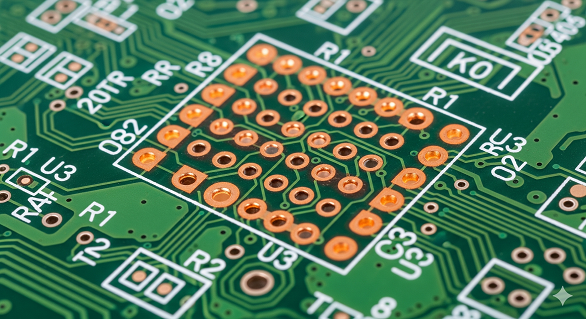

Copper balance is key in PCB fabrication, ensuring signal integrity, thermal management, and reliability by managing copper distribution for efficiency.

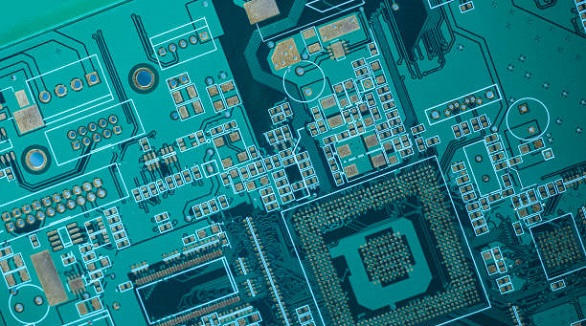

Choose the right PCB substrate based on application needs, balancing properties like Dk, Df, thermal conductivity, and cost, for optimal performance.

Fabric circuit boards blend electronics with fabrics, enabling wearables. FCBs offer flexibility, durability, and diverse applications across industries.

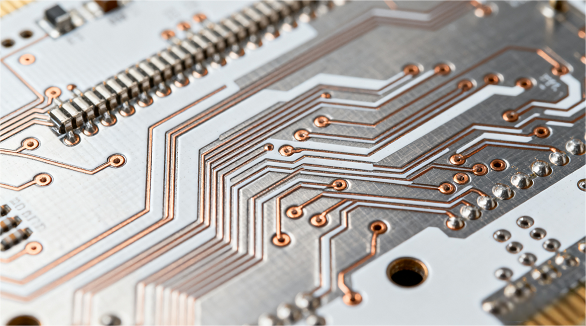

Laser tech revolutionizes PCB manufacturing with precision and efficiency, enhancing design, cutting, marking, and connectivity while reducing environmental impact.

Preheating PCBs enhances soldering by reducing thermal shock, improving wetting, and activating flux, using methods like conduction, convection, and IR.