PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

PCB plates provide vital support and customization in keyboards, impacting stability, sound, and performance, underpinning electronic design and evolution.

IPC Standards ensure quality, consistency, and global compatibility in PCB assembly, essential for innovation and reliability in electronics manufacturing.

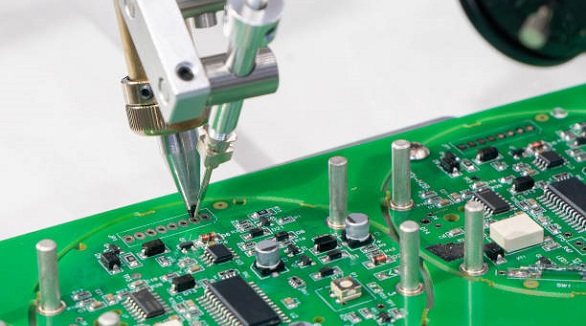

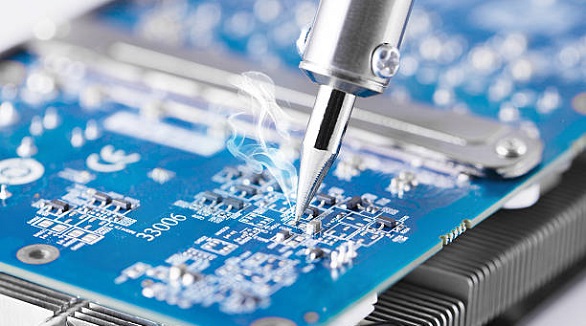

PTH soldering provides strong connections by threading component leads through PCB holes, requiring meticulous preparation and quality checks for lasting results.

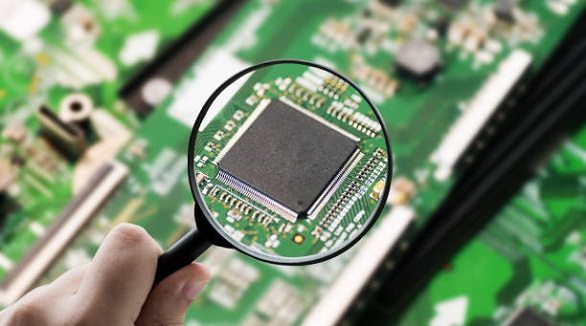

Rigorous PCB inspections using AI, AOI, and X-ray technology ensure high quality, reduce costs, and enhance efficiency in electronics manufacturing.

Smart door locks advance home security with convenience and tech, utilizing PCBs for functions like connectivity and access, critical to smart home growth.

ESD standards like ANSI/ESD S20.20 protect electronics from electrostatic damage, ensuring product reliability and reducing risks in manufacturing.

CTI measures PCB material's resistance to electrical tracking, ensuring safety and reliability in electronic circuits, crucial for design and manufacturing.

PCB edge mounting optimizes space, enhances modularity, and improves connectivity by placing connectors on board edges, aiding in flexible, efficient system design.